E307C BLADE CYL KIT 169-7826 ที่ทํางานได้ดี

1รายละเอียดสินค้า

E307C BLADE CYL KIT ที่มีประสิทธิภาพสูงนี้ (ส่วนที่ # 169-7826) เป็นจุดสูงสุดของเทคโนโลยีประปาไฮดรอลิกโดยเฉพาะเจาะจงออกแบบเพื่อทนต่อการใช้งานในภาระงานที่รุนแรงในกรณีที่ความล้มเหลวไม่ใช่ตัวเลือกโดยใช้วัสดุที่ทันสมัยและการผลิตแม่นยํา ชุดนี้ให้ผลประกอบการปิดที่ไม่มีคู่แข่ง ในสภาพการทํางานที่ท้าทายที่สุดการให้ความมั่นใจว่าอุปกรณ์ของคุณจะรักษาผลผลิตสูงสุดในช่วงที่สําคัญที่สุด.

| ชื่อสินค้า |

E307C BLADE CYL KIT 169-7826 ที่ทํางานได้ดี |

| ใช้สําหรับ |

ชุดประปาไฮดรอลิกซิลินเดอร์ |

| ประเภทของผนึก |

ชุดเครื่องปักสําหรับกระบอก ชุดเครื่องปัก |

| อุณหภูมิ |

ปรางกลอุณหภูมิสูง |

| ความเร็ว |

ปรางเครื่องจักรกลความเร็วสูง |

| เลขส่วน |

169-7826 |

|

ผลงานที่ดีที่สุด ทนต่อน้ํามัน |

| ธาตุประปา |

สต๊อปซีล รองเท้าปั๊ม ปิสตันซีล แหวนสวมแหวนฝุ่น แหวน O-ring แหวนสํารอง |

| วัสดุประกอบกับเครื่องประปา |

TPU, NBR, FKM, PTFE |

คุณสมบัติและข้อดีของพรีเมี่ยม

การใช้งานในภารกิจสูง พร้อม

เครื่องยนต์ที่ใช้งานในเครื่องยนต์

รักษาความสมบูรณ์แบบของผนึกภายใต้ภาระหนักต่อเนื่อง

เหมาะสําหรับการทําเหมืองแร่ การก่อสร้าง และการใช้งานที่หนัก

สูตรที่มีความทันสมัยสําหรับอุณหภูมิสูง

รักษาประสิทธิภาพการปิดที่ดีที่สุดในสภาพแวดล้อมอุณหภูมิสูง

ป้องกันการแข็งแรงและแตกในสภาพจักรยานความร้อน

รับประกันผลงานที่คงที่ในแอพลิเคชั่นความตึงเครียดสูง

ความสามารถในการปิดความเร็วสูง

ปรับปรุงให้เหมาะสมกับการใช้งานในวงจรเร็วโดยไม่เสี่ยงอายุการใช้งานของซีล

การออกแบบการขัดแย้งที่ลดลง ช่วยลดการสร้างความร้อนให้น้อยที่สุด

รักษาความแน่นในระหว่างการเคลื่อนไหวแบบไดนามิก

การคัดเลือกวัสดุชั้นนํา

สารผสมพอลิเมอร์ที่มีความทันสมัย ให้ความทนทานต่อการสวมเสื้อสูงสุด

ความต้านทานต่อการบดออกที่สูงกว่าในสภาพความดันสูง

ความเข้ากันได้อย่างดีเยี่ยมกับน้ําเหลวไฮดรอลิกทุกชนิดที่มาจากน้ํามัน

การแบ่งแยกองค์ประกอบทั้งหมด

อุปกรณ์ประปาทั้งหมด:

ปรางไม้เข็มที่ใช้งานหนัก

แหวนปั๊มความดัน

ผนึกพิสตันที่มีประสิทธิภาพสูง

แหวนนําแบบทนทานการสวมใส่

วงแหวนฝุ่นที่ปิดกั้นสารปนเปื้อน

การปัก O-Ring ความแม่นยํา

แหวนสํารองทนต่อการดึงออก

การสนับสนุนการรัดสต๊อป

เทคโนโลยีวัสดุที่ทันสมัย

TPU (โพลียูเรธานเทอร์โมพลาสติก)

ความทนทานต่อการบดและความสามารถในการแบกภาระ

รักษาความยืดหยุ่นภายใต้แรงกดดัน

NBR (Nitrile Butadiene Rubber)

ความทนทานสูงต่อสารไฮดรอลิกที่มาจากน้ํามัน

คุณสมบัติของชุดการบดอัดที่ดี

FKM (Fluoroelastomer)

ผลงานที่โดดเด่นในอุณหภูมิสูงถึง 400 °F +

ความทนทานทางเคมีที่ดีต่อของเหลวที่รุนแรง

PTFE (โพลีเทเทตราฟลูโรเอเธลีน)

คออฟฟิชั่นการขัดขัดต่ําสุดสําหรับการลดการสกัด

ความทนทานต่อสารเคมีและอุณหภูมิอย่างพิเศษ

2. รูปแบบบริษัท

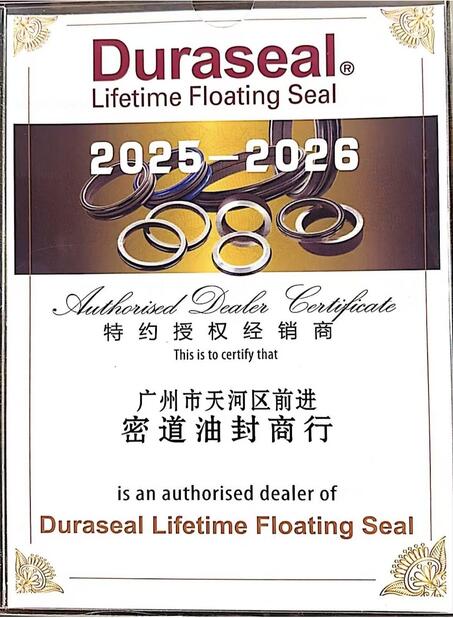

ก่อตั้งในปี 2007 Mido Oil Seal ได้เติบโตขึ้นเป็นผู้จําหน่ายเชี่ยวชาญของเครื่องประปาน้ํามันสําหรับอุตสาหกรรมเครื่องจักรก่อสร้างและเครื่องจักรกลเรารวมผนึกคุณภาพสูงจากผู้ผลิตชื่อดังทั่วโลก, ปัจจุบันมีสินค้ามากกว่า 1,000 สายพันธุ์ที่แตกต่างกันเพื่อตอบสนองความต้องการของตลาดที่หลากหลาย

การดําเนินงานของเราได้รับการสนับสนุนจากร้านค้าสามแห่ง และโกดังกลางที่ถูกออกแบบเฉพาะสําหรับงานต้อนรับลูกค้าและงานแสดงสินค้าที่สําคัญยิ่งกว่านั้น เราภูมิใจที่มีทีมงานมืออาชีพและมีประสบการณ์ ที่บริหารทุกขั้นตอนของกระบวนการ จากการจัดซื้อและขายและบริการหลังการขายที่น่าเชื่อถือ.

กรรมการผู้จัดการของเรา คุณฮู มีความเชี่ยวชาญในอุตสาหกรรมมาตั้งแต่ปี 1995 ในฐานะสมาชิกผู้ก่อตั้ง และอดีตประธานสมาคมอุตสาหกรรมเครื่องจักรก่อสร้างกวางโจวเขามีความเข้าใจอย่างลึกซึ้งในตลาดบํารุงรักษาเครื่องขุดในจีนภายใต้ความเป็นผู้นําของเขา เราเรื่อยๆวิจัย นวัตกรรม และพัฒนาชุดซ่อมแซมผนึกที่มีประสิทธิภาพสูง ที่ตรงกับความต้องการของตลาดในโลกจริงผลิตภัณฑ์ของเราถูกออกแบบมาเพื่อให้มีประสิทธิภาพสูง, ปิดกันการรั่วไหลที่มีความทนทานยาวนาน

นําโดยหลักการของความเป็นผู้นําทางเทคโนโลยี, Mido Oil Seal ได้สร้างระบบที่ครอบคลุมรวมถึงการวิจัยตลาด, การประกันคุณภาพ, และการสนับสนุนลูกค้าซึ่งทําให้เราสามารถตอบสนองความต้องการของลูกค้าได้อย่างแม่นยําการสร้างชื่อเสียงที่ดีและส่งเสริมความร่วมมือที่ยั่งยืนกับลูกค้าทั้งในประเทศและต่างประเทศ

เราเข้าใจว่าการนําผลิตภัณฑ์ของเรามาใช้อย่างสําเร็จนั้น ขึ้นอยู่กับความไว้วางใจและความร่วมมือของคุณ" มุ่งมั่นในการให้บริการของน้ํามันดีเยี่ยม.

นอกเหนือจากแพลตฟอร์มการขายออนไลน์ของเราแล้ว เรายังมีส่วนร่วมในงานแสดงสินค้าในอุตสาหกรรม เพื่อส่งเสริมการเชื่อมโยงที่แข็งแกร่งและตรงหน้ากับลูกค้าของเรา

เราชื่นชมความคิดเห็นของคุณอย่างแท้จริง การสนับสนุนที่ต่อเนื่องของคุณขับเคลื่อนเราให้ยังคงดีขึ้น และเราพยายามที่จะทําให้ความร่วมมือของเราแข็งแกร่งมากขึ้น

FAQ

Q1. ทําไมผมต้องเลือกสินค้าของคุณ?

ขณะที่ดําเนินงานในโรงงานผลิตของเราเอง เรายังจําหน่ายเครื่องประทับน้ํามันจากแบรนด์ชื่อดังระดับนานาชาติเรามุ่งมั่นที่จะให้บริการแก้ไขที่หยุดเดียว เพื่อตอบสนองความต้องการที่หลากหลายของลูกค้าของเราชุดปิดเครื่องขุด / เครื่องบรรทุก / เครื่องปรับเครื่องยนต์และอะไหล่

Q2. บริษัทของคุณมีสินค้าชุดไหน?

ชุดปิดเครื่องขุด/เครื่องบรรทุก/เครื่องปรับเครื่องยนต์ และอะไหล่

Q3 มีบริการดีอื่นๆ ที่บริษัทคุณสามารถให้บริการได้หรือไม่

ใช่ครับทําการตรวจติดตามเป็นประจํา และมีพนักงานที่บริการตลอด 24 ชั่วโมง

ในยุคของสํานักงานดิจิตอล บริษัทของเรามุ่งมั่นที่จะให้บริการลูกค้าด้วยประสบการณ์การบริการที่ครบวงจรและมีประสิทธิภาพ"การตอบสนองจากผู้เชี่ยวชาญออนไลน์" เป็นองค์ประกอบสําคัญของความมุ่งมั่นนี้.

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!